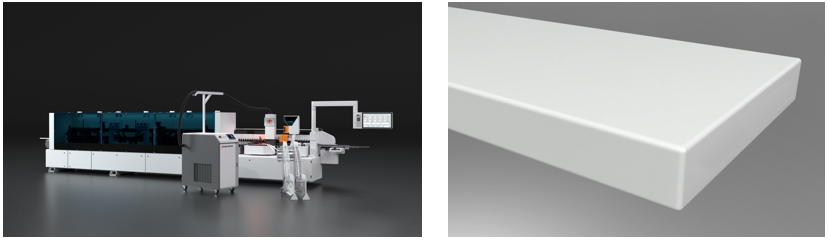

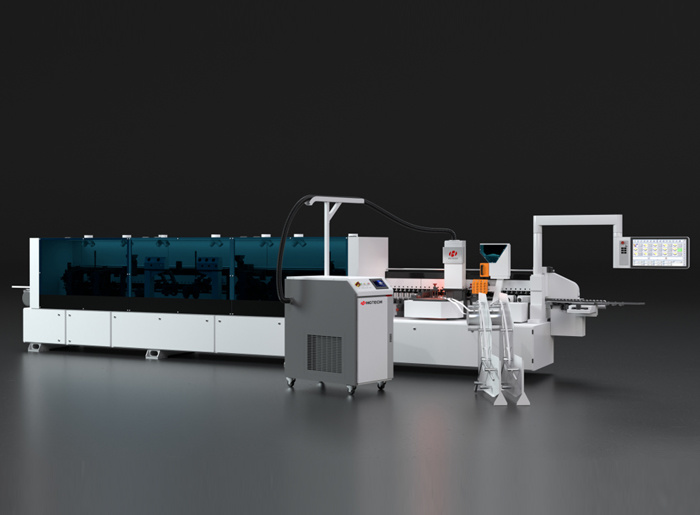

LaserHead Series

Laser Edge Sealing Module

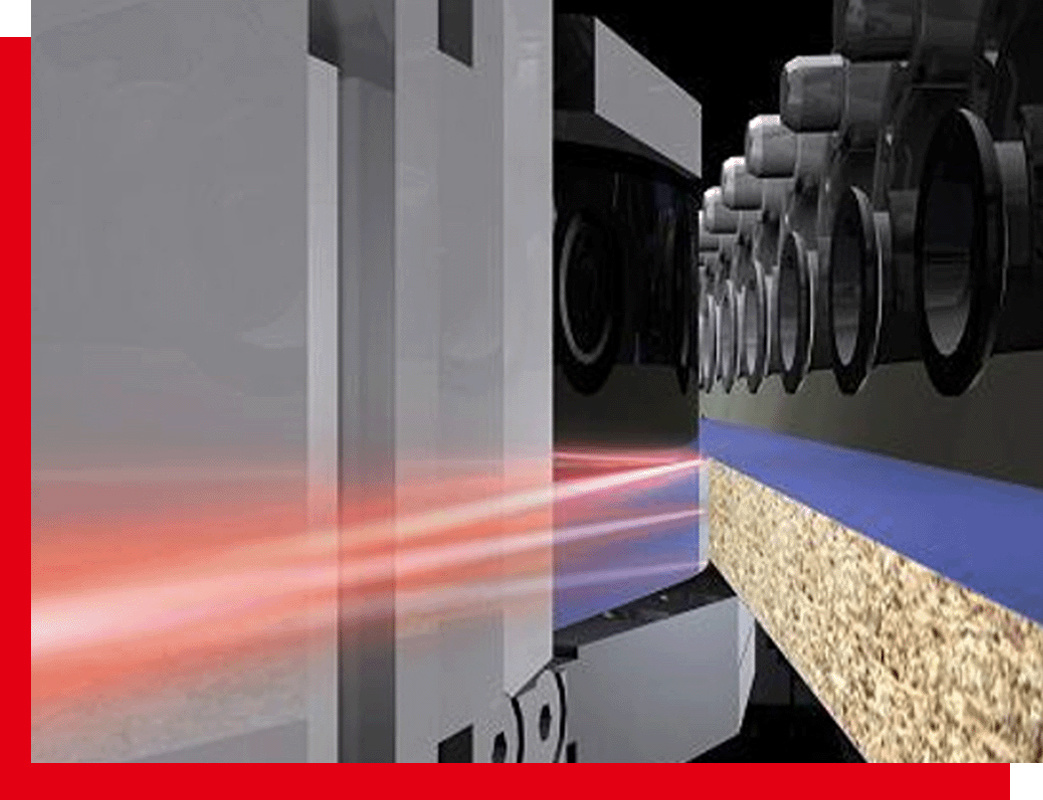

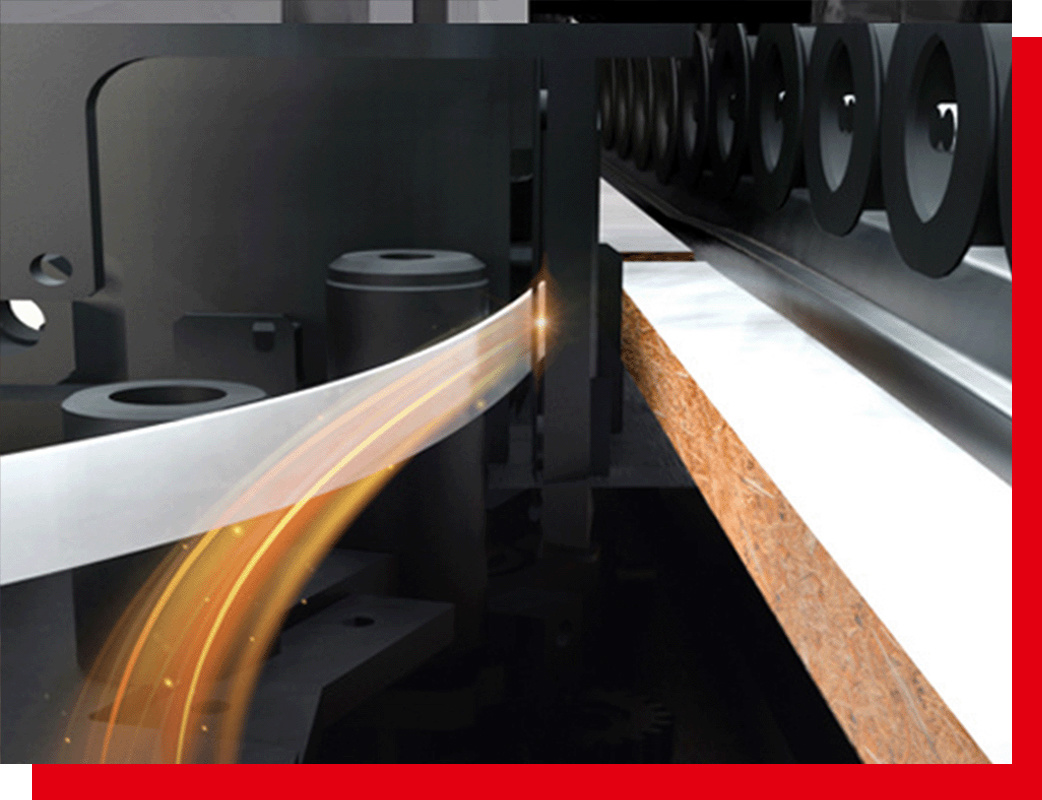

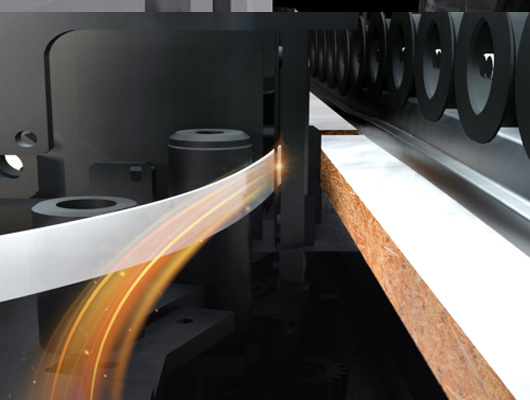

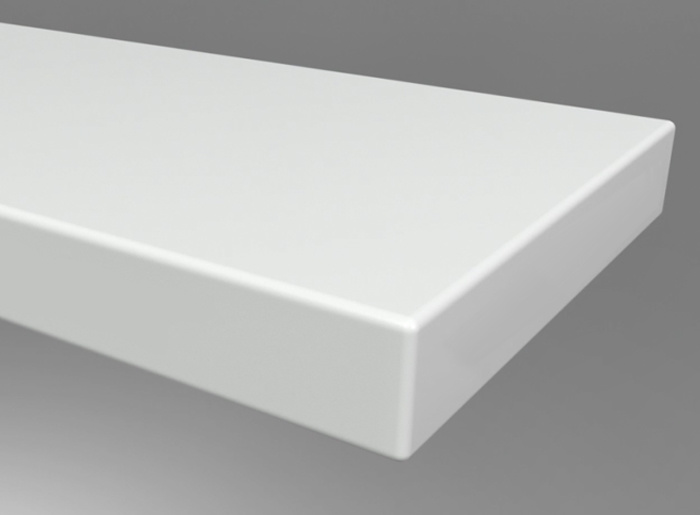

Laser edge sealing is the use of high energy density of the laser beam, precise control on the surface of the edge band with a special coating, the plate and edge band perfect combination process. At the same time, the polymer of the edge band fills the gap between the plate and the edge band, the edge band and the edge band, and achieves seamless and intact edge sealing quality. At the same time, the entire edge sealing process is very fast, no heating waiting, instant edge sealing production, the material is also very environmentally friendly, can achieve visual and functional permanent, completely seamless bonding, wear resistance at the same time moisture resistance and heat resistance is also very good.

- Product Features

- Product Features

- Application Scenarios

- Product Parameters

- Product size

- Application example

-

产品简介

Modular designPerfect adaptation with various types of edge banding machine

Modular designPerfect adaptation with various types of edge banding machine Perfect Edge SealingEdge banding and plate perfect fit without glue seam

Perfect Edge SealingEdge banding and plate perfect fit without glue seam Safety and environmental protectionEffectively reduce the formaldehyde emission of edge sealing plate

Safety and environmental protectionEffectively reduce the formaldehyde emission of edge sealing plate

Homogenize the wobbling spot

- The laser head uses high-speed click to focus into a point

- The laser beam swings back and forth at high speed perpendicular to the direction of the edge band,

- Technology to achieve the combination of edge banding fast sol and plate.

Homogenize rectangular spot

- Through optical technology, the laser hair emits a rectangular spot,

- And adjust the spot height with the operation program,

- The laser energy is continuously and uniformly emitted to the edge band of the corresponding size.

-

Product Features

Modular designPerfect adaptation with various types of edge banding machine;

Modular designPerfect adaptation with various types of edge banding machine; Perfect Edge SealingEdge banding and plate perfect fit without glue seam;

Perfect Edge SealingEdge banding and plate perfect fit without glue seam; Safety and environmental protectionEffectively reduce the formaldehyde emission of the edge sealing plate.

Safety and environmental protectionEffectively reduce the formaldehyde emission of the edge sealing plate.

Detailed description of spot type

Homogenize the wobbling spot

Laser head using high-speed click will focus into a point-like laser beam

Swing back and forth at high speed perpendicular to the direction of the edge band,

Technology to achieve the combination of edge banding fast sol and plate.

Homogenize rectangular spot

Through optical technology, the laser hair emits a rectangular spot,

And adjust the spot height with the operation program,

The laser energy is continuously and uniformly emitted to the edge band of the corresponding size. -

Application Scenarios

-

Product Parameters

LaserHead laser edge sealing series

Equipment Model

LaserHead 3030S

LaserHead 3030

laser power

3000W

3000W

Working conditions

Power

AC380V±10%/50Hz

Compressed air

0.6-0.7MPa

Coolant

Distilled/Deionized Water

Ambient temperature

10 ℃-40 ℃

Working environment humidity range

30%~70%

Workpiece size

workpiece thickness

9mm-36mm, common size 18mm, 22mm, 25mm

Edge Banding

Edge banding thickness

Laser edge sealing 1mm-3mm

Edge banding width

Thickness of board (4~6mm)

laser energy density

≤ 26J/cm2

Edge speed

Speed

Open tracking feed speed ≤ 25 m/min,

(The maximum value is measured at the normal feed speed of 18mm plate, and the actual working speed depends on the actual plate thickness)

Laser head status

Laser spot type

scanning spot

rectangular spot

Laser spot working range

≤ 50mm (scanning rate up to 10000 mm/s)

10mm-40mm (automatic continuous adjustable)

System Control

Machine, electric and soft interactive interlocking

Optical/mechanical/electrical/soft linkage control, alarm interaction, to achieve safety interlock

-

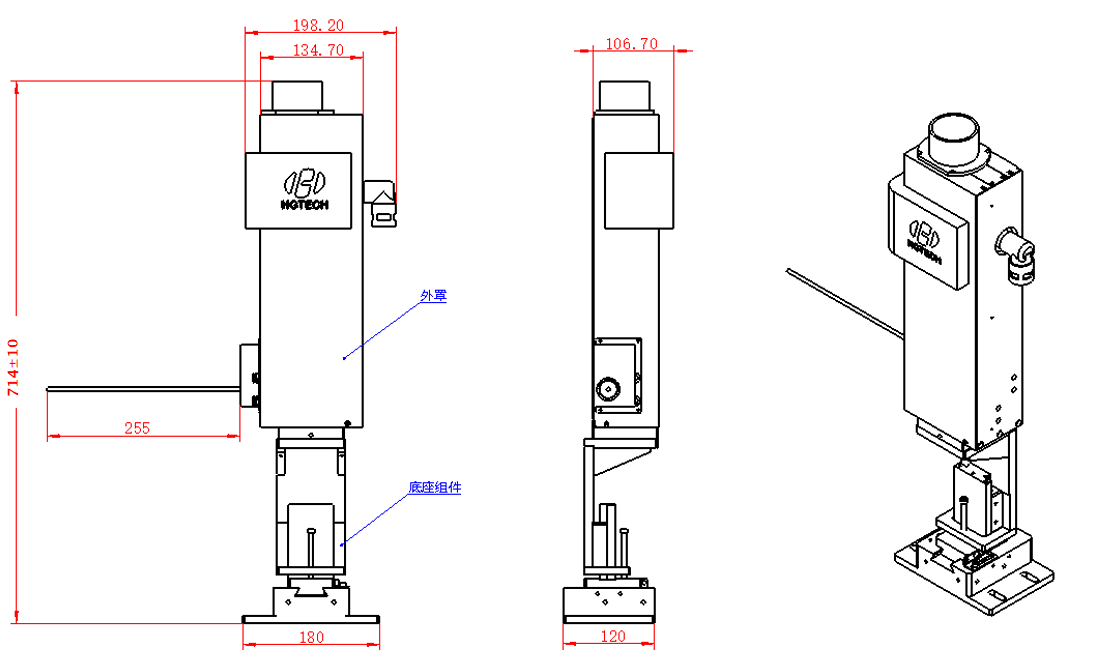

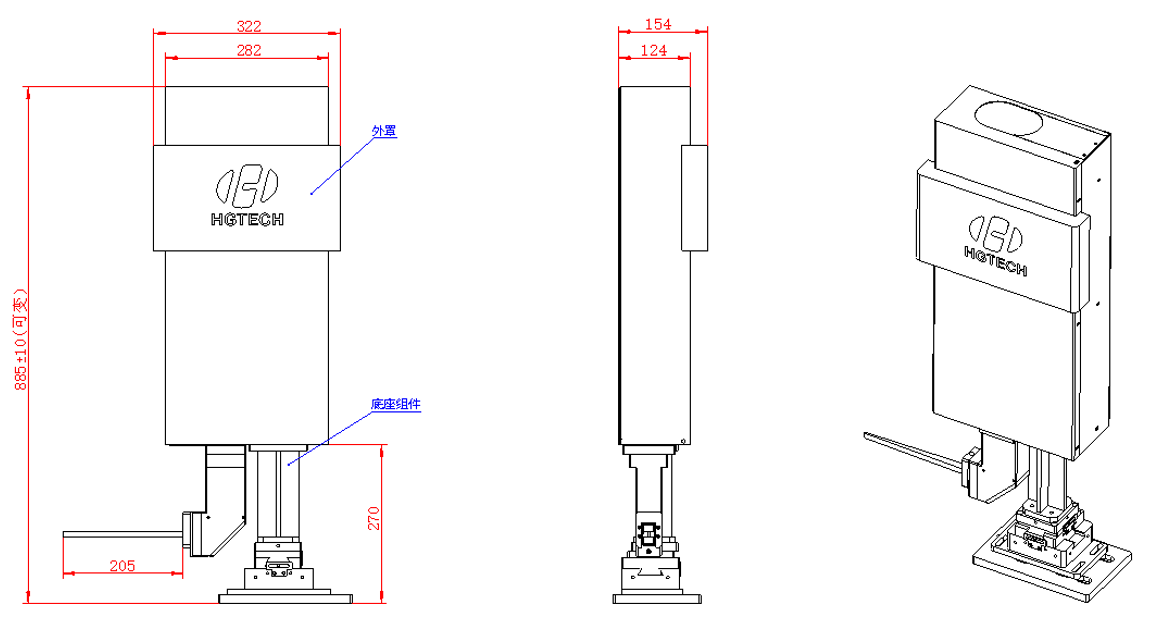

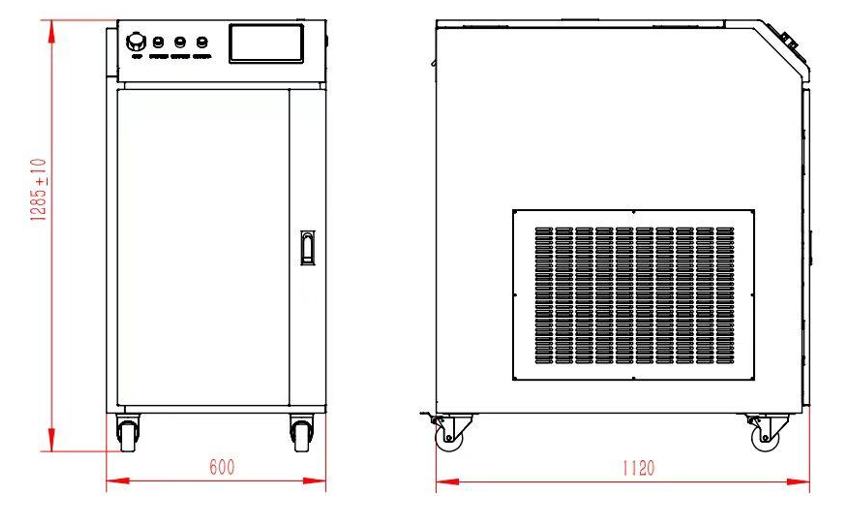

Product size

Scanning spot processing head size (installed on the edge banding machine)

Rectangular light spot processing head size (installed on the edge banding machine)

Part size of chassis (placed near edge banding machine)

-

Application example

Previous Page

Next Page

Application areas

Application 12

Application 13

Related Products