To calculate the economic account, why must the cable mark be laser?

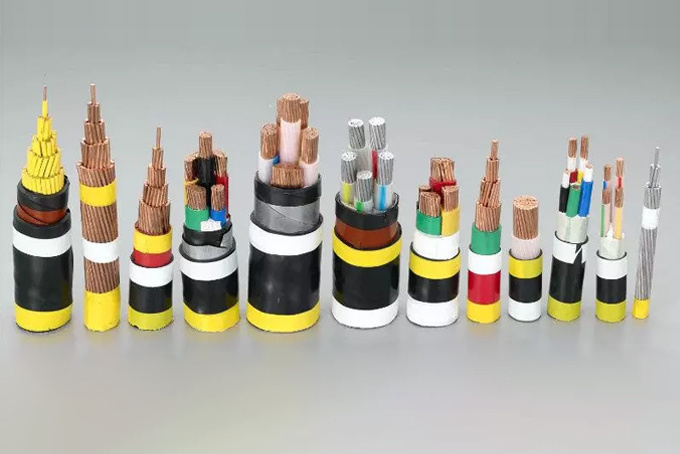

In recent years, with the rapid development of my country's economy, the wire and cable industry has also grown. In 2017, the scale of China's wire and cable industry reached 1.2 trillion billion yuan, an increase of 6.3 over the same period in 2016. Industry market size to maintain rapid and stable growth, the national production and sales of wire and cable has surpassed the United States to reach the world's first.

During the 13th Five-Year Plan period, the total investment in China's distribution network construction is expected to reach 1.7 trillion billion yuan, with an average annual investment of 340 billion. It is planned that by 2020, the length of high-voltage distribution network lines will reach 1.01 million kilometers, and the length of medium-voltage distribution network lines will reach 4.04 million kilometers.

At the same time, the "13th Five-Year Plan" also formulated a rural power grid transformation and upgrading plan with a total investment of more than 700 billion yuan. It can be seen that during the "13th Five-Year Plan" period, my country's power cable market demand is strong.

With the increase in demand for wire and cable, improving efficiency and reducing costs have become a major problem for manufacturers, so many manufacturers are looking for new production processes.

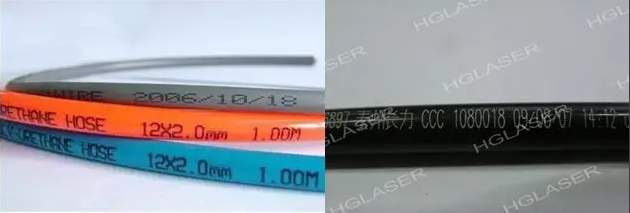

Taking the cable surface marking process as an example, after the original ink spray code is replaced by laser coding technology, the production efficiency, processing effect and production cost have been improved in an all-round way.

Consumables Cost

-

ink spray code:The cost of consumables for an ink inkjet printer is 2-40000 yuan per year. It is understood that the cost of ink purchased by a medium-sized enterprise in a year should reach 40-500000 or even millions.

-

Laser coding:No consumables cost.

Running time

-

ink spray code:Ink jet printer is affected by the working environment and temperature and humidity changes, easy to produce ink and nozzle blockage phenomenon, high failure rate, short service life of equipment.

-

Laser coding:It can realize 24h stable continuous production, and the service life of fiber laser inkjet printer can reach more than 100000 hours.

Marking speed

-

ink spray code:Using manual or mechanical operation, it can realize 1 line or more lines of character marking, and the relative speed is slow.

-

Laser coding:Using computer integrated intelligent operation, can realize automatic feeding, automatic marking, automatic storage, save time; marking speed is faster.

Labor cost

-

ink spray code:The ink inkjet printer has many processes, requires continuous addition of ink, and frequent cleaning of the nozzle for maintenance, and limited storage of consumables.

-

Laser coding:It can realize automatic online flight marking and reduce working procedures. And the development speed is fast, the marks can be continuously replaced, the storage capacity is large, basically no manual maintenance is required, and the operation is simple.

Comparison of marking effect

As an advanced marking equipment, laser inkjet printer is replacing traditional marking equipment because of its many advantages and has become the latest choice for wire and cable manufacturers. Smart manufacturers all know how to choose between ink spray code and laser spray code?

Flying ultraviolet series laser marking machine, independently developed by huagong laser, uses high energy density ultraviolet laser to process workpieces without contact, with high marking accuracy, fast speed and clear marking. you deserve to have ~

Related recommendations

New Products Starts | LASER HEAD Laser Edge Seamless System Starts, Apears Seamless "Wisdom" to Create Beauty

View DetailsIn-depth analysis... Huagong Laser takes you a report to read the safety behind the mask.

View DetailsScience and Technology Save "Food": Chinese Workers Laser Plays with Easy Tear Line of Food Packaging ~

View DetailsSpecialized in special new | visual inspection "eyes", good medical equipment quality off!

View Details