Specialized in special new | visual inspection "eyes", good medical equipment quality off!

Visual detection replaces the human eye, really?

Disposable syringes are commonly used in medical supplies and are closely related to our lives. As our consumers pay more and more attention to medical product hygiene, manufacturers are paying more and more attention to medical product testing due to brand reputation considerations and production yield needs.

After many syringe manufacturers use visual inspection instead of manual inspection, the quality and production efficiency have been greatly improved. Is it really so magical? Laser Jun will give you the answer.

Disposable syringes are composed of needles, rubber plugs, core rods and syringes, which may have foreign bodies such as black spots and hair during the production and assembly process; missing rubber plugs, needles and needle sheaths, abnormal surface scales of syringes, etc. may occur in the packaging process, which seriously affect product quality.

The "golden eye" of machine vision can replace the human eye in industrial production and automatically detect the appearance and interior of the product. Its work efficiency and detection accuracy are far higher than manual work, and the product yield is greatly improved.

Strict quality level

Huagong LaserBased on machine vision inspection technology, we independently developed the industry-leading general vision algorithm library HG-Vision, and built the industry's first medical device product defect detection system, which is suitable for the quality inspection of disposable sterile syringe high-speed production line.

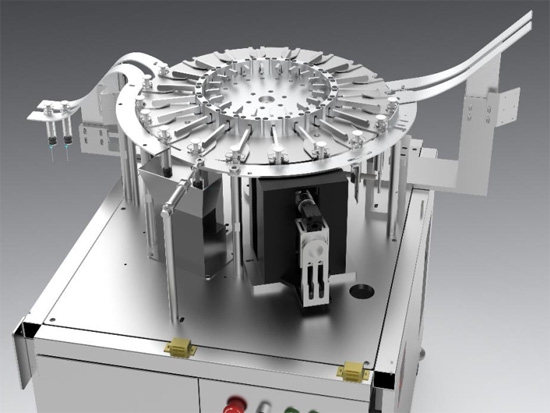

Disposable syringe defect detection equipment

The 360-degree omni-directional visual inspection system can accurately capture internal and external defects, and the qualified rate of one-time inspection can reach 99.98, accurately eliminating NG products, reducing costs and increasing efficiency.

Customized needs. Can be directly connected to the customer's existing production line, high-speed detection, detection efficiency as high as 20000/hour, suitable for 5-50ml syringe detection.

Data pictures are saved in real time, logs can be saved and exported, and remote monitoring of production records is supported.

304 stainless steel material, in line with the medical device industry safety standards, to adapt to the harsh medical production environment.

In addition to disposable syringe vision inspection applications, Huagong Laser's vision inspection system can also be used for other quality inspections in the medical device industry.

Medical device packaging quality inspection equipment

It is used to detect the packaging quality of various products, and accurately detect products with problems such as product position deviation, wrong scale orientation, multiple materials, and shortage of materials after syringe packaging.

With more than 50 years of technology precipitation, Huagong Laser has created specialized and special new products to help medical industry enterprises reduce costs and increase efficiency, while working with enterprises to protect the quality of medical device products and the medical safety of our whole society!

Related recommendations

New Products Starts | LASER HEAD Laser Edge Seamless System Starts, Apears Seamless "Wisdom" to Create Beauty

View DetailsIn-depth analysis... Huagong Laser takes you a report to read the safety behind the mask.

View DetailsScience and Technology Save "Food": Chinese Workers Laser Plays with Easy Tear Line of Food Packaging ~

View Details