In-depth analysis... Huagong Laser takes you a report to read the safety behind the mask.

Laser+Medicine Big Health

How to solve the problem of mask recognition and anti-counterfeiting.

The importance of identity to products and brands is self-evident. The traditional identification method mainly uses ink spray code technology, but the biggest disadvantage of this technology in the current process of producing masks is the inability to be flexible and environmental pollution problems, which also leads to the special period of large-scale expansion of masks can not meet production needs.

Laser applications can be a good solution to the above problems.Flexible production of laserAt present, it has been used in large quantities in the production and manufacturing of all walks of life. Compared with ink, it is more environmentally friendly and highly identifiable, and has been recognized and used by a large number of food companies. Huagong Laser for the current mask market identification problems related to process development and experiments, the launch of a newLaser ink-free printing technology, can be high-quality to solve the mask product identification, improve the overall quality of the product, from the quality to enhance the mask brand influence.

(Photo from Sina Finance)

The following laser jun will take you to read the laser marking of medical protective masks through detailed reports and analysis.

01

Principle of laser marking for medical protective masks

Material Properties

Medical protective mask is a non-woven material, composed of oriented or random fibers, generally a multi-layer structure, usually referred to as SMS structure (2 layers of S layer and 1 layer of M layer). At present, the highest number of layers in China is 5 layers, namely SMMMS(2 layers of S layers and 3 layers of M layers). S represents a spunbond layer (Spunbond) and M represents a barrier or meltblown layer M(Meltblown), all composed of polypropylene (PP). M layer with meltblown nonwovens as the filter layer, because of its fiber is randomly distributed and complex three-dimensional porous, the biggest characteristic is composed of ultrafine fibers, the specific surface area of the fiber is large, the adsorption capacity of particles is strong; Meltblown filter material fibers are randomly distributed, forming a large number of tiny pores, and the pore distribution is uniform, the filtration resistance is small, and the filtration efficiency is high, the filtration performance of non-woven medical protective masks is far better than that of traditional gauze masks.

SMS non-woven fabric with polypropylene PP (with natural antibacterial and hydrophobic) as the main raw material, the fiber diameter can reach 0.5-10um, these ultra-fine fibers with unique capillary structure increase the number of fibers per unit area and surface area, so that the meltblown cloth has good air filtration, is a good mask material. Therefore, the laser marking surface is a non-woven fabric made of S-layer polypropylene material.

Laser marking

Laser marking and ink printing masks contrast

Like all medical and health products, anti-counterfeiting marks are an important part of mask products.

Today, compared to the traditional ink printing technology,laser markinghasNon-toxic, non-polluting, high efficiency, high definition, high precision, wear resistanceIt has technically solved a series of problems of traditional ink printing. It can be said that laser marking technology has been escorting the medical industry since its birth.

The principle of laser marking technologyMainly the use of high energy density of laser irradiation on the surface of the material, so that the surface of the material surface gasification to expose the deep material, or under the action of light irradiation on the surface of the material can make the color change of chemical reaction, leaving a permanent mark marks. Since laser processing is non-contact processing, the tool will not directly friction with the surface of the workpiece to produce resistance, soThe speed of laser processing is extremely fast, and the range of heat-affected objects is small.andWill not produce noise. Since the energy of the laser beam and the moving speed of the beam can be adjusted, the laser processing can be applied to different levels and ranges.

At present, there are two recognized laser processing principles: laser thermal processing and photochemical processing (also known as cold processing). Huagong laser this time chose a short wavelength ultraviolet laser for marking process.

short wavelength ultraviolet laserWhen acting on the polymer, the chemical bond of the material is directly broken, so that the material fragments are discharged in a small particle or gaseous manner, so as to achieve the purpose of stripping and removing the material, thus producing a smooth, clear and easy to distinguish mark inside the material. Since most of the energy is used to break chemical bonds, very little energy is converted into heat energy, which can basically eliminate the change of heat affected zone (HAZ) and surrounding materials, and ensure that the material will not be deformed by heat.

cold working(Ultraviolet) photons with very high load energy can break chemical bonds in materials (especially organic materials) or surrounding media, resulting in non-thermal destruction of materials. This kind of cold processing is of special significance in laser marking processing, because it is not thermal ablation, but does not produce "thermal damage" auxiliary, breaking the chemical bond of cold peeling, and therefore on the surface of the processing of the inner layer and the vicinity of the area does not produce heating or thermal deformation.

Because the heat generated by the thermal processing light source will cause damage to the outer and middle surface of the mask, the mask filter has a greater impact, so the Huagong laser selection of "cold processing" ultraviolet laser to mark the mask surface.

02

Influence factor of laser marking for medical protective masks

Laser marking speed

Influence of different marking speed on marking effect

Laser marking speed is the distance of laser scanning per unit time,The action time of the laser and the material can be controlled by changing the marking speed.

The above is the change of the surface effect of different marking speeds on the material. As can be seen from the figure, the marking speed adopted by Huagong laser this time is from2000mm/s-5000mm/s, The effect changes from coke yellow to moderate effect. When the marking speed is slow, the interaction time between the laser beam and the material per unit area is longer, the carbonization of the laser beam and the material surface material is more intense, and the thermal influence increases, which leads to the marking effect turning yellow and the marking contour line becoming thicker. When the marking speed is gradually accelerated, the interaction time between the laser beam and the material is reduced, so that the laser beam and the material surface material carbonization intensity is reduced, when the marking speed is a specific value, the carbonization is more moderate, to obtain the best contrast.

Laser marking speed

The effect of different marking frequencies on the marking effect.

The laser repetition frequency is the number of laser light output per unit time, and when the marking speed is constant, the spot overlap rate is affected. Figure 2 (B) compared to Figure 2(a) marking effect is yellow. Analysis of the reason, in the case of the same laser power, 60kHZ laser peak power is the highest, the same time the material to absorb the energy of the laser beam increases, the thermal impact increases and yellowing.

Hatch Line Spacing

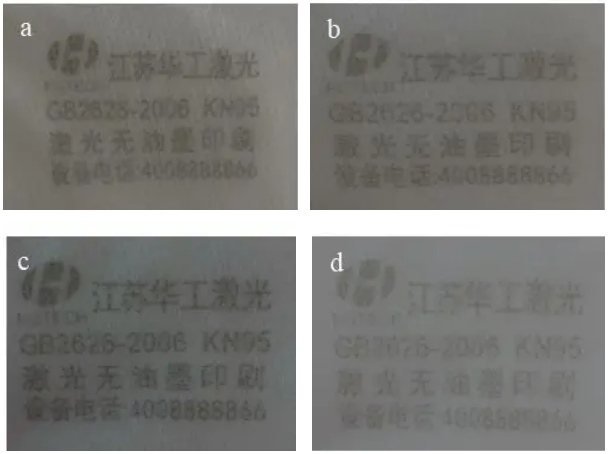

The effect of hatch spacing on marker effects.

(a)0.08mm;(b)0.12mm;(c)0.15mm;(d)0.2mm

Fill line spacing refers to the distance between two adjacent fill lines when lines are used to fill text or patterns that require marking. The line spacing is too small, the marking time is long, and the heat influence of the material is serious, resulting in the contour lines being bonded together, and the marking effect is poor (as shown in Figure 3(a)); the line spacing is too large, the marking time is short, and the marking effect is not obvious (as shown in Figure 3(d)).

02

Effect of laser marking on the filtration rate of medical protective masks

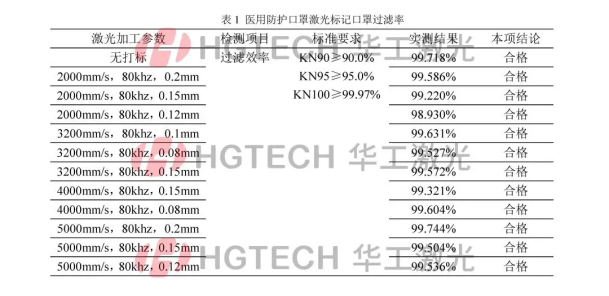

In order to test the impact of laser marking on the core index of masks-filtration performance, Huagong Laser carried out strict filtration rate and performance tests on the materials after laser marking.Huagong laser-marked materials have little effect on filterability and performance..

Huagong Laser commissioned a third-party agency to test the filtration rate of masks marked with different laser process parameters, and the test results are shown in the figure below. The mask is marked by the laser marking technology of Huagong laser, and the filtering of the mask is not affected after setting the appropriate marking parameters.

Huagong Laser Ultraviolet Laser Medical Mask Marking Test Report

The use of Huagong laser ultraviolet laser can mark medical protective masks, different laser process parameters (frequency, marking speed, filling line spacing) have a significant impact on the mask marking contrast.

The use of laser marking on medical protective masks has no effect on the filtration rate of masks, and the filtration rate of masks after marking meets the national standard.

Based on more than 20 years of process and technical advantages in the laser field, Huagong Laser provides professional laser marking solutions for a number of mask enterprises, and has recently shipped a number of laser equipment for mask enterprise production.

Jiangsu Huagong Laser Technology Co., Ltd. (hereinafter referred to as Jiangsu Huagong Laser) is a wholly-owned subsidiary of Wuhan Huagong Laser Engineering Co., Ltd., located in Suqian, the core area of Huaihai Economic Zone.

Jiangsu Huagong Laser's Flying UV series coding equipment has a maximum power of 20W. Its domestically developed short-wavelength UV laser has excellent performance, smaller focus spot, shorter time on materials, less thermal effect and more beautiful marking effect, has been widely used in medicine, medical, personal care products, food and beverage packaging and other products on the effective date, batch number, shift, manufacturer name and logo and other graphics and text marks.

Making good use of the power of science and technology, relying on a sound market service system and efficient and fast service quality, Huagong Laser will cheer for China with you.

Related recommendations

New Products Starts | LASER HEAD Laser Edge Seamless System Starts, Apears Seamless "Wisdom" to Create Beauty

View DetailsScience and Technology Save "Food": Chinese Workers Laser Plays with Easy Tear Line of Food Packaging ~

View DetailsSpecialized in special new | visual inspection "eyes", good medical equipment quality off!

View Details